Chassis Resonance Control

It is estimated that 40–50% of an audio system’s distortions come from unwanted resonances from both within the component from the transformer vibration, via mechanical feedback loops, and from airborne vibrations.

Removing or reducing these unwanted resonances results in a more clarity with more fine detail resolution; high frequencies become more natural, and soundstage and dynamics are increased.

Harmonic Resolution Systems

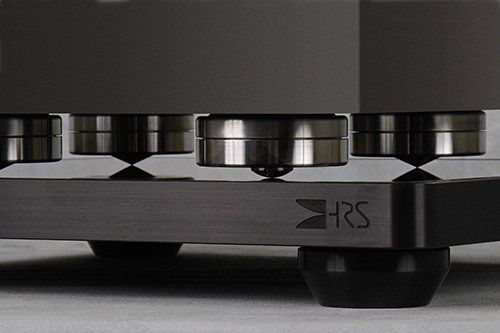

Nimbus Couplers and Spacers

Nimbus Assemblies

The Nimbus Assemblies consists of two Couplers factory bonded either side of a high density aluminium Spacer. Whilst these two components can be purchased separately the bonded Nimbus Assembly makes for easier installation.

This is placed under the chassis of a piece of audio equipment in intimate contact with the bottom surface, avoiding the existing feet and any bolts or protrusions. Clearly a minimum of 3 ‘footers’ is needed but more enhances the effect. Four, or even five if space allows, gives further improvements to the sound quality.

The Coupler part of the Nimbus Assembly is fundamental part of the HRS technology. This is a highly researched polymer compound which is broadband resonance absorber. This totally absorbs vibration and noise at the point of contact - across the frequencies we listen to. Hence it is more efficient that other products that rely on hard materials, such as metal or ceramic, which transfer the energy from the chassis to the supporting surface but do not actually deal with this unwanted resonance.

Most of the chassis resonance is created by the transformers present in all electronic components. These unwanted resonances create noise within the circuit boards and are heard as distortions. Placing the Nimbus Assemblies against the chassis completely removes these resonances. The bottom Coupler to the Nimbus Assemblies also completely stops any structure borne vibration coming through the support system via acoustic feedback at that point. Most equipment supports, no matter how well constructed they are, still "leak" bass energy from loudspeakers feeding back through the shelves.

Because HRS products work in a different way to other isolation feet such as Stillpoints, Pulsar Points or even Cera-products from Finite Elemente, they produce a much cleaner, more natural sound due to a very obviously lower noise floor. These other mechanical devices rely on transferring unwanted resonances from one side to the other. This resonance has to go somewhere and far too often it remains within the support system, and can come back as reflections. The alternative technologies often rely on a steel or ceramic ball to transfer energy, and this can, of course, go both ways. Hence the control of structure borne energy - ie feedback from the bass energy generated by loudspeakers - cannot be totally successful. The HRS Nimbus Assemblies uses two polymer barriers to vibration energy transfer and removes it completely at point of contact. Hence it is more efficient and a complete solution for the removal of mechanical noise.

The effect on the sound of the equipment is immediately apparent. The result is one of a far more transparent sound, less high frequency distortion ("fizz"), and a quieter, blacker, background. This lower noise floor allows low level detail to be more more easily perceived resulting in a more focussed image, a more holographic sound stage, and a more natural, less "hi–fi" presentation.

As might be expected, the Nimbus Assemblies work incredibly well under turntables too.

The Nimbus Assemblies and the Damping plates are designed to work as a complete system. The best results are obtained if you ‘sandwich’ your equipment between the Nimbus Assemblies and the Damping Plates. There is no true benefit from just using one part over the other. The total effect is more than the sum of the parts. Once heard you will not be able to listen to your system without them. Do not forget to treat separate power supplies; this is usually where the transformer and associated circuit boards reside.

One customer who tried the HRS items against his existing Stillpoints reported:

Great and essential stuff. I always believed the flaw in the Stillpoints sound was due to a cabling problem... It's not funny how you can go wrong in audio land and may end up compensating for the wrong kind of tweaks in my system... Also surprised by how effective they (HRS Nimbus) are under the power supply. Bass is not less, perhaps even more but civilised.

Mr H v d L, Holland

Trial sample packs for home evaluation of the HRS effect can be arranged to suit particular requirements. This usually consists of a kit of 4 Nimbus Assemblies and a Damping Plate suitable for the component. We can help recommend the best package for your particular trial. No obligation to purchase. All we ask is that, if no sale results, our delivery costs are covered.

Nimbus - Black only

Couplers £96.00 (pack of two)

NS-030 Spacer 86 mm (d) x 8 mm (h) £50.00

NS-080 Spacer 86 mm (d) x 20 mm (h) £55.00

NS-130 Spacer 86 mm (d) x 33 mm (h) £65.00

These combinations are more often purchased as a bonded assembly, see below, whereby the Couplers are factory glued to the Spacer. This makes it easier to place under most electronic components particularly if they are heavy.

Nimbus Assembly - Black only

NA-100 86 mm (d) x 25 mm (h) £135.00

NA-150 86 mm (d) x 38 mm (h) £145.00

NA-200 86 mm (d) x 51 mm (h) £155.00

Discounts available for mail order purchases of any HRS chassis noise reduction products more than £700 in one order. Please phone for details.

For information on the ADL or the new ADH Record Weight, please look under the Vinyl Replay section of our website. Prices: ADL £265, ADH £485

Nimbus Assemblies

Couplers as cable supports

We have recently tried the Couplers as cable supports and found they give exemplary results in this application. The Coupler material is a broadband resonance absorbing polymer, the technology being unique to HRS. It is very easy to hear the effects of lowering the noise floor by removing the acoustic feedback loop from speaker energy transferred through the floor. Simple to use and discrete in operation when used under signal cables and power cords that contact the floor. For a speaker cable run of 2.5 m to 3.0 m, approximately 4 or 5 Couplers will be required to support the cable clear of the floor depending on the cable stiffness. At £86 for a pack or two, they also offer exceptional value for money for the level of sonic upgrade achieved.

Paul Rigby, The Audiophile Man, also agreed with our evaluation and has written the following review:

Paul Rigby (The Audiophile Man) Accessory Review

NEW

Helix

HRS have introduced a new product called Helix which is a development of the Vortex - see the section below for a detailed description. This is specifically designed for components with stiffer and heavy metal chassis. Like the Vortex it employs a Coupler made from a less compliant polymer, but the housing is a simpler construction made from aircraft grade aluminium, similar to the Spacers used in Nimbus Assemblies. Each Helix has a stainless-steel screw part with a shallow rounded profile to allow height adjustment – a special tool is included to allow the adjustment to made in situ.

With many metal chassis, even those made from plate metal, they are not always perfectly flat, and the adjustable foot allows for each Helix to make intimate contact with the bottom surface of the chassis. The adjustable part is alos ona gimbal to self level in use. The deliberately designed shallow profile means it has low visibility in use. The screw thread allows for a height between 18mm and 30mm.

The sound improvement with the Helix is, as expected, some way between the Vortex and the Nimbus Assemblies. When used in the correct context they deliver a low noise floor enabling low level detail to be heard more easily, greatly enhancing image focus, and a more holographic sound stage. For more detail, please read the description to the Vortex below.

Sold in sets of 3 but up to 5 can be used for larger chassis for optimal results.

HLX-090 – set of 3 £425

HLX-090 – single £145

Discounts available for mail order purchases of any HRS chassis noise reduction products more than £700 in one order. Please phone for details.

Vortex

This is a chassis noise reduction device is designed to work with the thicker and stiffer chassis that some larger and heavier electronics are made from. They are similar to the Nimbus Assemblies but are constructed from a stainless steel outer with the HRS proprietary damping medium incorporated within the Vortex, and a Nimbus Coupler at the top that is designed to contact with the bottom plate of a chassis, not the steel outer. This Coupler is a less compliant polymer and befits the application against heavier and stiffer, metal plate chassis.

With direct metal contact (such as Stillpoints, Cerabase, and Pulsar points) the main result is a brighter, more forward sound. The custom material interface used within the Vortex steel outer case was optimized to push the limits of resolution and dynamics without brightness, fatigue, or high frequency noise. HRS developed the new polymer material specifically for the Vortex primarily to get the best of all musical qualities combined. With final two versions of prototype Vortex, HRS listened to many different types of recordings, and on many systems. Neither of them ever allowed the system to become bright, or have high frequency noise artefacts. They specifically listened for that negative effect during testing to ensure real lifelike speed and dynamics, but also to noise artefacts that just do not exist in a live performance.

The Vortex come in two versions. The V-150 is a fixed height design which has a shallow, but not sharp, point at the underside. This will not mark delicate surfaces such as metal or granite. The V-150A has an adjustable height steel part underneath. This has a fine thread to adjust height precisely and is on a gimbal to allow self levelling. A tool is supplied to do this height adjustment when this V-150A is placed underneath the chassis. In many instances chassis are not always flat, even if thick metal is used, hence when 4 or more Vortex units are used, this adjustable module ensures intimate contact of all Vortex modules with the underside of the chassis being treated.

From the first evaluation tests with the new Vortex assemblies the benefits were immediate and obvious. Just placing 3 Vortex modules under a chassis constructed with 13 mm thick aluminium plate, and another 3 under the separate power supply similarly constructed, produced an astonishing and exceptional improvement to the sound. Just a few seconds into the piece of music being played, the sound improvements were evident and not subtle. This is compared to the same piece of electronics already sitting on 3 NA-150 Nimbus Assemblies and on top of a M3X-1921 base, The improvement in sound quality using the Vortex was a surprise. Better transparency, wider and deeper soundstage (it was not bad before!), better separation of instruments and voices, faster transient attack and dynamics.

A complex early music vocal piece with 6 singers was much easier to follow as the reduced noise floor resulted in improved articulation. Images were better focussed, with more air around the singers within the tangible space that the recording was made in. There was no increase in brightness and the presentation was not more forward, as there can be with other steel/ceramic balls designs from competitive brands such as Stillpoints, Cerabases or Pulsar Points. The sound stage is enlarged - deeper and wider.

Removal of high frequency distortions is what Nimbus products do well anyway. The Vortex assemblies take this to a whole new level.

A further unexpected result was when the 4th adjustable Vortex assembly was placed under the chassis. A further step change occurred but this time the main benefit was to the tonal balance. There was more authority to the bass end of the frequency range which gave a more realistic balance to the timbre of instruments and voices, with added texture to strings being bowed or plucked. The complex resonances of a piano were more evident and the decays of sustained notes were extended.

We have demonstration samples for home evaluation. For owners of electronics constructed from thick plate or billet, such as Edge, Boulder, Constellation, Ayre, or Solution, we highly recommend an audition of this product to allow you to hear the true potential of these designs. Please note that with normal, thinner metal sheet chassis, the standard Nimbus Assemblies would still be the first recommendation.

V-150 (fixed height assembly) £365

V-150A (adjustable height assembly) £395

V-150 Set (3 x V-150 plus 1 x V-150A) £1395

Discounts available for mail order purchases of any HRS chassis noise reduction products more than £700 in one order. Please phone for details.

Damping Plates – DPII Series

Damping Plates DP II Series – Black or Silver

Small DPII-05545 (4.5" x 5.5"; 114 x 140 mm) £175

Medium DPII-09545 (4.5" x 9.5"; 114 x 241 mm) £240

Large DPII-14545 (4.5" x 14.5"; 114 x 368 mm) £295

Discounts available for mail order purchases of any HRS chassis noise reduction products more than £700 in one order. Please phone for details.

The

DPII Series of Damping Plates is designed to damp the vibrations to the top part of an audio component chassis. This is mainly caused by airborne vibrations from playing music in the listening room. Even music played quietly feeds back unwanted resonances to the chassis. Try the knuckle test and tap the top surface. You may be surprised how resonant it is, even on components that are expensive to buy. The polymer compound, similar to that used in the

Nimbus Assemblies, absorbs the vibration completely on contact and is held in place by the aircraft grade aluminium, which also adds mass.

The DPII damping plates are designed to used in conjunction with the Nimbus Assemblies, Helix, or Vortex components placed under the bottom of the chassis. They come in 3 sizes. One damping plate covering approximately 70% of the surface is advised. If this cannot be achieved with one plate, a second damping plate optimises the noise reduction.

Damping Plates – DPX Series

HRS offer a thicker Damping Plate called DPX Series which has more than twice the thickness of aircraft grade aluminium. The damping polymer remains the same as in the DPII range. These plates have more than twice the mass and many more times the stiffness of the standard DPII plates. Mainly for use with thicker plate chassis but can be very beneficial with almost any electronic component. The upgrade in sound by using the DPX version by lowering the noise floor even more is much more than would be suggested with the price difference. At least twice the sonic improvement for around 32% increase in price An extremely audible upgrade and good value at the respective price points.

The DPX Series comes in three sizes, combinations of which will work with almost any chassis. One Damping Plate will produce a good result but, if the area is large enough, up to three pieces will give further improvements.

The Damping Plates and the Nimbus Assemblies are designed to work as a complete system. The best results are obtained if you ‘sandwich’ your equipment between the Nimbus Assemblies and the Damping Plates. There is no true benefit from just using one part over the other. The total effect is more than the sum of the parts. Once heard you will not be able to listen to your system without them. Do not forget to treat separate power supplies; this is usually where the transformer and associated circuit boards reside.

Damping Plates DP X Series – Black or Silver

DPX-05545 Small (4.5" x 5.5"; 114 x 140 mm) £220

DPX-09545 Medium (4.5" x 9.5"; 114 x 241 mm) £320

DPX-14545 Large (4.5" x 14.5"; 114 x 368 mm) £390

Discounts available for mail order purchases of any HRS chassis noise reduction products more than £700 in one order. Please phone for details.